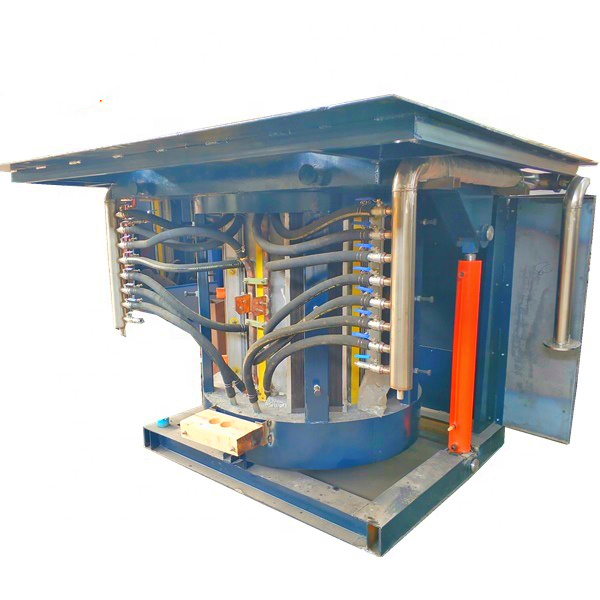

Using Intermediate Frequency Furnace to Improve Casting Efficiency

In the metal foundry industry, the efficiency and effectiveness of the melting process is critical to achieving high-quality castings. Industrial melting furnaces play a pivotal role in this process, and one of the furnaces that has gained popularity is the intermediate frequency furnace.

At Runxiang Machinery, we prioritize innovation and quality, and our foundry intermediate frequency furnaces are specially designed and manufactured to meet the needs of the foundry industry.

The meaning of intermediate frequency furnace:

The intermediate frequency furnace is an industrial smelting furnace using the principle of intermediate frequency electromagnetic heating. The technology ensures fast and efficient melting of scrap metal and metal scrap, making it ideal for foundries. It belongs to the category of metal remelting, which allows the inclusion of trace alloying components to improve the performance index of castings.

Efficiency and Accuracy:

One of the main advantages of our intermediate frequency furnaces is the ability to reach high temperatures quickly, reducing overall melting time. This not only increases productivity, but also saves a lot of energy. In addition, the use of trace alloying components allows precise control of the metallurgical properties of the casting, resulting in improved quality and performance.

Processes are seamlessly integrated:

In Runxiang Machinery, we have a complete industrial chain covering all the necessary processes to achieve excellent results in the foundry industry. With our steelmaking, casting, heat treating, machining and surfacing capabilities, we ensure seamless integration of processes, saving our customers time and resources.

Quality assurance:

We understand the importance of producing high quality castings and our induction furnance can guarantee this. Our research and development team works tirelessly to optimize the design and functionality of our furnaces, ensuring they meet and exceed industry standards. Additionally, our dedication to using high-quality materials and advanced manufacturing techniques ensures the durability and reliability of our products.

The foundry industry relies heavily on efficient and precise melting processes to produce high-quality castings. The intermediate frequency furnace provided by Runxiang Machinery can not only meet these requirements, but also exceed expectations with its advanced technology and complete industrial chain. Our furnaces use the principle of medium frequency electromagnetic heating to ensure fast and precise melting of scrap metal, ultimately improving the performance indicators of castings. With Runxiang Machinery’s intermediate frequency furnaces, foundries can increase efficiency, reduce energy consumption and produce premium castings of the highest quality.